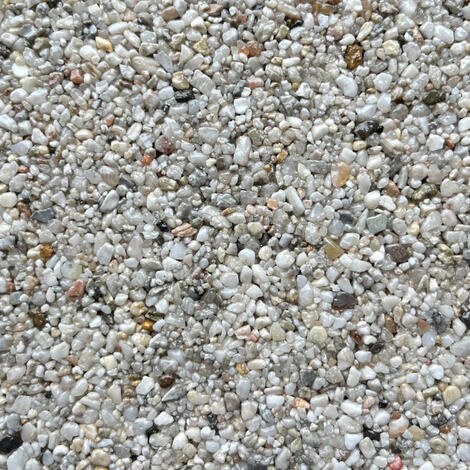

VUBA Binding Quartz, 5KG

Vuba-binding quartz is translucent and has reduced absorbency. This reduces the 'sandy' and 'matt' finish associated with adding 'sand' to resin-bound mixers.

Vuba binding quartz will provide added slip and skid resistance for driveways and increase the strength of a resin-bound screed by 42% in tests carried out by Vuba in accordance with BS EN 12390 - 3: 2009.

How to Buy VUBA Binding Quartz, 5KG

Can be purchased as a single item.

Also available to pick up from our depots in Ferndown, Bournemouth, and Dorchester.

Visit the Christchurch Showroom if you want to see the trims on display.

Why Do We Need Resin Binding Quartz

Resin-binding quartz, or using a resin-bound system for quartz aggregates, is essential in various applications for several reasons:

Enhanced Durability: Resin-bound quartz surfaces are highly durable. The resin acts as a binding agent that locks quartz granules tightly together, forming a strong, long-lasting surface resistant to cracking, weathering, and heavy traffic. This makes it ideal for outdoor settings like driveways, patios, and pathways, as well as high-traffic indoor areas.

Aesthetic Appeal: Resin binding allows for the creation of smooth, seamless surfaces with a modern look. Quartz offers a range of natural colours and textures, and when combined with resin, the result is visually appealing, with options for customizing colour schemes to match different design preferences.

Permeability: A resin-bound quartz surface allows water to permeate through, preventing issues with standing water and puddles. This makes it an eco-friendly solution by aiding proper drainage and reducing the risk of flooding in areas like patios or driveways.

Low Maintenance: Resin-bound quartz surfaces are non-porous, which prevents the growth of weeds, moss, or algae. This results in a low-maintenance solution, as it requires minimal cleaning and upkeep compared to traditional paving or concrete.

Slip Resistance: The resin-bound quartz surface has a natural grip, offering excellent slip resistance, even in wet conditions. This makes it a popular choice for pool surrounds, walkways, and driveways, enhancing safety.

UV Resistance: The resin used in binding quartz is UV-stable, meaning it won’t yellow or fade over time due to sun exposure. This ensures that the surface maintains its appearance for a longer period, particularly in outdoor settings.

In summary, resin-binding quartz provides a durable, visually appealing, safe, and low-maintenance surface that is well-suited for both indoor and outdoor environments.

Binding Quartz As a Part of a Resin Kit

Binding quartz to resin-bound aggregates is part of the process of creating a durable, visually appealing, and porous surface for outdoor areas such as driveways, patios, and pathways. Here's how the process generally works:

Selecting the Quartz Aggregate:

Quartz is chosen as one of the primary aggregates for its strength, colour, and texture. It's available in various sizes and colors, allowing for customized finishes. Aggregates can be a mix of quartz, granite, marble, or other materials, depending on the desired look.

The size of the quartz aggregate typically ranges between 1mm to 10mm, depending on the texture and use case for the resin-bound surface (e.g., finer for paths and courtyards, coarser for driveways).

Mixing the Resin:

A two-part clear polyurethane or epoxy resin is mixed. The resin acts as a binder, holding the quartz and other aggregates together.

The resin is usually mixed using a forced-action mixer to ensure an even consistency. Once mixed, it is ready for the aggregates to be added.

Adding the Quartz to the Resin:

After mixing the resin, the quartz and other chosen aggregates are introduced into the mixer with the resin.

The aggregates and resin are combined in the forced-action mixer, ensuring each piece of quartz is evenly coated with the resin. The ratio of resin to aggregate is important to achieve the correct binding strength and permeability. Generally, the mix will consist of about 4-5% resin by weight.

This ensures that the quartz is fully embedded within the resin, providing a uniform and durable surface once laid.

Laying the Resin-Bound Quartz Mix:

Once the quartz and resin are mixed, the blend is poured onto the prepared surface (usually a compacted, stable base like concrete or asphalt).

The mix is then spread using trowels to create a smooth, even finish. The thickness of the layer is typically 15-20mm depending on the application.

Curing:

The resin-bound quartz surface needs time to cure. Typically, the curing process takes between 4-6 hours, but this can vary depending on the weather conditions and the type of resin used.

During this period, the resin hardens and binds the quartz together, forming a solid, seamless surface.

Resin-Bound Aggregates vs. Porcelain Paving

| Feature | Resin-Bound Aggregates | Porcelain Paving |

|---|---|---|

| Aesthetics | Natural, rustic appearance with colour choices | Sleek, modern, and polished look |

| Permeability | Permeable (SUDS-compliant) | Non-permeable (requires drainage) |

| Durability | Durable but may not handle heavy loads | Extremely durable, resistant to heavy traffic |

| Slip Resistance | High slip resistance due to textured surface | Slip-resistant but depends on the finish |

| Maintenance | Low maintenance, but repairs can be tricky | Very low maintenance, easy to clean and repair |

| Installation | Flexible, can be laid over existing surfaces | Requires more skill and preparation |

| Ideal Use | Driveways, paths, areas needing drainage | Patios, pathways, pool decks, driveways |

Resin-bound aggregates are ideal for those who want a natural, flexible, and permeable surface that complements garden paths, driveways, or eco-conscious projects.

Porcelain paving is the go-to choice for a sleek, modern look with superior durability, particularly in high-traffic areas or for creating sophisticated, low-maintenance outdoor living spaces.

Each material offers unique advantages, and the choice between them depends on your specific requirements for aesthetics, maintenance, and functionality.

Buy With Confidence

- Our VUBA Binding Quartz can be purchased as single items

- Please enter the amount of trims you need (for example 20sqm would be 8 Trims).

- All of our Trims come in crates which can be easily placed into a van or into a garden using a hiab lorry.

- You can choose a free collection from one of our Depots or fuss-free, home delivery.

A Service You Can Rely On

- Our trustworthy service offers prompt delivery to any area in the UK

- Stone Zone is a family-run business that has been well-established since 1998

- Our knowledgeable customer advisors can help you with your purchase

- We pride ourselves on offering a range of affordable garden supplies

Delivery information

Related Blog Article

VUBA Resin Bound Surfacing

VUBA Resin Bound SurfacingStone Zone is delighted to be the newest stockist for VUB …